Caterpillar 6D16 Engine Camshaft Removal and Installation Guide

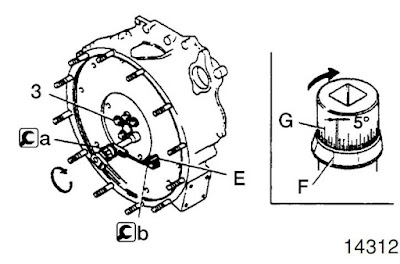

This instruction show you Caterpillar 6D16 engine camshaft removal and installation guide. Procedures: Camshaft end play If the end play measurement exceeds the specified limit, replace the defective part(s). Inspecting engine speed sensor Cat com 3 adapter <Models with electric speed sensor> • Measure the electrical resistance between terminals ➀ and ➁. • If the measurement is out of specification, replace the speed sensor 1. P.11-55 CAUTION Check the tightening torque of the engine speed sensor 1. If the sensor is insufficiently tightened, it may not produce signals. Fitting side cover • Apply an even, unbroken bead of sealant A to the side cover 5. • Fit the side cover 5 onto the crankcase within 3 minutes of applying the sealant A. Cat ET 2022A CAUTION • Ensure that the sealant application surface of the side cover 5 is clean before applying sealant. • When fitting the side cover 5, hold it firmly in position to prevent spreading the sealant. • After fitting the side cover 5,