Caterpillar 6D16 Engine Time Gears Service Procedures

This instruction show you guide on how to do time gears service for Caterpillar 6D16 engine.

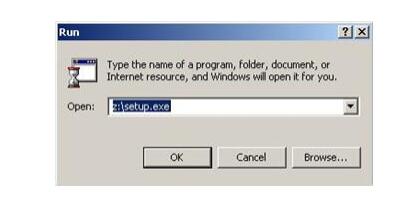

Cat ET Adapter 3

Procedures:

(1) Gear backlash

For each gear pair, measure backlash at three or more points. If any measurement exceeds the specified limit, replace the defective part(s).

(2) Idler gear end play

If the measurement exceeds the specified value, replace the defective part(s).

No. 1 idler shaft and No. 1 idler gear bushing

[Inspection]

If the clearance exceeds the specified limit, replace the defective part(s).

Caterpillar ET 2022A

No. 1 idler gear bushing

[Removal]

A: Press

[Installation]

• Using the Idler Gear Bushing Puller, press the No. 1 idler gear bushing 3 into the No. 1 idler gear 4 from the side of the gear whose internal diameter is chamfered B.

A: Press

• After installation, measure the clearance again. If the measurement is below the nominal value range, ream the bushing 3.

Removing No. 1 idler shaft and No. 1 idler gear Loosen the bolt 1 by approximately 15 mm (0.591 in.), then remove the

No. 1 idler shaft 2 and No. 1 idler gear 4 as a single unit.

Installing No. 1 and No. 2 idler gears

Fit the No. 1 and No. 2 idler gears 4, 12 such that their alignment marks (“1”, “2”, “3”, “4”) are aligned with those on the gears with which they mate.

*1: Drive gear

*2: Camshaft gear

*3: Crankshaft gear

Caterpillar SIS EPC

No. 2 idler gear bushing and No. 2 idler shaft

[Inspection]

If the clearance exceeds the specified limit, replace the defective

part(s).

No. 2 idler gear bushing

[Removal]

A: Press

[Installation]

• Using the Idler Gear Bushing Puller, press the No. 2 idler gear bushing 11 into the No. 2 idler gear 12 from the side of the gear whose internal diameter is chamfered B. A: Press

• After installation, measure the clearance again. If the measurement is below the nominal value range, ream the bushing 11.

Removing No. 2 idler shaft 13

Comments

Post a Comment