Caterpillar 72H Pipelayer Jump Start Cables User Guide

This illustration show you guide on how to use jump start cable for Caterpillar 72H Pipelayer.Cat SIS EPC Download

Procedures:

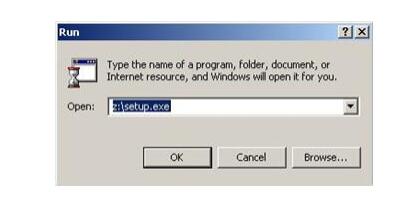

When the auxiliary start receptacles are not available, use the following procedure.

1. Determine the failure of the engine to start.Reference:

Use this procedure if the machine does not have a diagnostic connector.

2. Place the transmission control on the stalled machine in the NEUTRAL position. Engage the parking brake switch. Lower all attachments to the ground. Move all controls to the HOLD position.CAT ET 2022A

3. On a stalled machine, turn the start switch key to the OFF position. Turn off the accessories.

4. On a stalled machine, turn on the battery disconnect switch.

5. Move the machines together in order for the cables to reach. DO NOT ALLOW THE

MACHINES TO CONTACT EACH OTHER.

6. Stop the engine on the machine that is the electrical source. When you use an auxiliary power source, turn off the charging system.

7. Check the battery caps for correct placement and for correct tightness. Make these checks on both machines. Make sure that the batteries in the stalled machine are not frozen. Check the batteries for low electrolyte.

1

Note: Some positive cables and some covers for positive terminals are red for correct identification.

8. Connect the positive jump-start cable to the positive cable terminal of the discharged battery.

9. Batteries in series may be in separate compartments. Use the terminal that is

connected to the starter solenoid. Trace this cable in order to make sure that the cable is connected to the starter.

10. Connect the positive jump-start cable to the positive terminal of the electrical source. Use the procedure from Step 149 in order to determine the correct terminal.

11. Connect one end of the negative jump-start cable to the negative terminal of the electrical source.

12. Make the final connection. Connect the negative cable to the frame of the stalled machine. Make this connection away from the battery, the fuel,the hydraulic lines, or moving parts.CAT Adapter 3

13. Start the engine on the machine that is the electrical source. Also, you can energize the charging system on the auxiliary power source.

14. Allow the electrical source to charge the batteries for 2 minutes.

15. Attempt to start the stalled engine.Allow the electrical source to charge the batteries for 2 minutes.

16. Immediately after the stalled engine starts,disconnect the jump-start cables in reverse order.

17. Conclude with a failure analysis on the starting charging system. Check the stalled machine, as required. Check the machine when the engine is running and the charging system is in operation.

Comments

Post a Comment